Product Videos

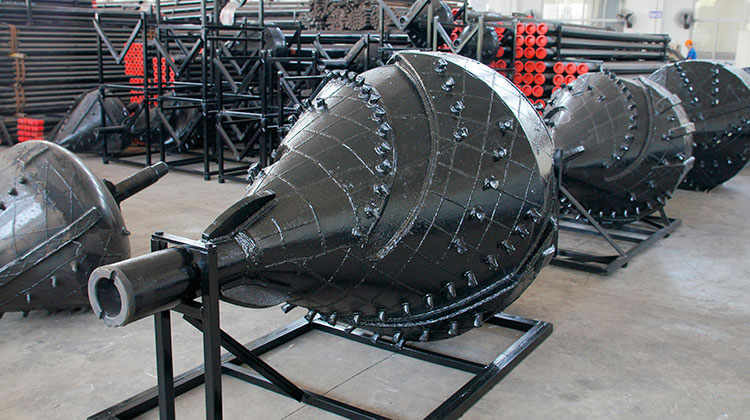

Factory

Wuxi Caston Drill Tools Co.,Ltd.

Add.: No.89 Zhenhubei Road, Wuxi City, Jiangsu province, P.R. China

Tel.: +86-510-85066207

Fax: +86-510-85066207

Please make sure that the video is paused before filling in the form.